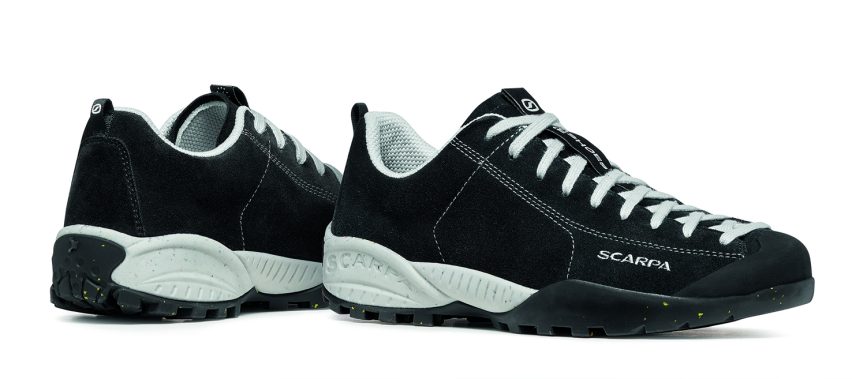

SCARPA, an Italian company specializing in the production of outdoor footwear for mountaineering, climbing, hiking, trail running, and ski mountaineering, officially presents the Mojito Re-Shoes, a reinterpretation of the iconic model inspired by the world of climbing.

Circular innovation and sustainable design: Mojito Re-Shoes is born

The new product has been entirely redesigned according to eco-design principles, representing a concrete and circular solution for managing the end-of-life of footwear within the production chain.

The Mojito Re-Shoes is the result of the LIFE Re-Shoes project, coordinated by SCARPA as part of the European Union’s LIFE programme, with the aim of integrating recycling as a structural practice in the footwear sector.

From recycling used shoes to producing new Mojitos

Thanks to a two-year collection campaign across the brand’s European distribution networks, SCARPA recovered enough used footwear to produce 15,000 pairs of Mojito Re-Shoes.

This significant milestone marks a concrete step toward reducing the use of virgin raw materials, emissions, and waste, offering a concrete solution to the problem of waste disposal in a market that produces approximately 24 billion pairs of shoes each year.

A new sustainable business model for the footwear industry

“With Mojito Re-Shoes, we demonstrate that it’s possible to combine functionality, design, and recycled materials in a single product,” comments Sandro Parisotto, President of SCARPA.

“This project represents a new starting point for the industry: the goal is to develop a business model in which end-of-life footwear becomes a resource for the production of new shoes, following a truly circular approach.”

Technology and materials: the heart of Re-Shoes innovation

The project is based on an advanced selective hydrolysis process, which allows the upper and sole to be separated, chemically regenerating the leather to obtain new material.

The worn out soles are ground and transformed into new midsoles, while the tread and reinforcements are made with high percentages of recycled material.

The percentages of recycled material

- Midsole: Up to 35% material derived from ground soles

- Sole: 50% devulcanized rubber from SCARPA production waste

Design for recycling: a shoe designed to be recycled

Traditional footwear is difficult to recycle due to the layering of heterogeneous materials. The Mojito Re-Shoes, however, was created according to the principles of design for recycling:

- elimination of metal eyelets

- reduction in the number of materials

- use of technologies that facilitate the separation of the upper and sole

An approach that makes the shoe easily recyclable at the end of its life, without sacrificing the aesthetics and performance that have made the Mojito iconic.

Digital traceability and life cycle analysis

The entire recycling and production process is digitally tracked and supported by an LCA (Life Cycle Assessment) analysis, which will provide timely data on emissions, water consumption, energy consumption, and chemicals used.

The partners of the LIFE Re-Shoes project

The project was developed in collaboration with leading industrial and academic partners, including:

- Alma Mater Studiorum – University of Bologna

- Rubber Conversion

- Rubbermac.it

- Innovando

- Charade Tanning Industry

- EPSI – European Platform for Sports and Innovation

Availability and sales channels

The Mojito Re-Shoes is available from today on the official SCARPA e-commerce site and will arrive in physical stores starting from the Spring-Summer 2026 season.