The story of F.lli Campagnolo and its brands is one of determination, resilience, ambition and commitment, the story of a Venetian family that from a condition of poverty, typical of the post-war period, has been able to develop an entrepreneurial reality of international importance, becoming a point of reference in the world of outdoor with the CMP brand and in activewear and home textiles with the other 5 brands owned. We went to Romano d’Ezzelino (VI), in their historic headquarters, to hear it told and to get to know first-hand one of those entrepreneurial realities that make us proud to be Italian.

4Outdoor is also on Whatsapp. Just click here to subscribe to the channel and stay up to date.

The commercial story of F.lli Campagnolo began way back in 1948, when Maria Disegni, a young widow with 5 children to raise, started a retail business on a stall at the Bassano del Grappa market. In 1954, the involvement of the Campagnolo brothers led to the opening of the first “Casa della lana” store and the beginning of the wholesale sale of hats and sweaters. In 1965, the F.lli Campagnolo brand was registered. Investments were made in textile machinery for jacquard production and by 1973 there were 200 employees. It became a joint stock company in 1980. In the 1990s, the company made the leap from a manufacturing company on behalf of third parties to a company with proprietary brands.

Fabio Campagnolo interview

CEO CMP

What were the key stages that marked the history and growth of F.lli Campagnolo?

Jumping back to the beginning of our story, we were born as manufacturers in the 70s, distinguishing ourselves in the sportswear sector. When compulsory gymnastics classes were introduced in schools, my mother had the intuition to start producing tracksuits, first for children, and then to expand the offer to women and men. At that time, the few tracksuits available on the market came mainly from the United States and my father had already gained good experience in the production of fabrics. Later, one of our representatives told us that Puma was looking for a partner for the production of tracksuits: that’s how we started a collaboration with them, followed by others with international brands such as Reebok. This allowed us to establish ourselves and consolidate our know-how in the fields of weaving and dyeing; and when economic logic induced brands to move production to Eastern Europe rather than Asia, we began to focus on our brands. The next step was to introduce other items into the catalogues that were not part of our traditional production, namely knitwear and fleece, such as ski suits. In 2010, F.lli Campagnolo changed to CMP, a more functional name suited to international markets. Growth in terms of distribution and the opening of numerous single-brand stores over time led us to expand the CMP offering: clothing was developed for more sports activities and we also introduced footwear and accessories, such as backpacks, helmets, masks, glasses and trekking poles.

The group today has a turnover of approximately 240 million euros and CMP contributes 90%: which markets do you cover and which of them is the most prosperous in terms of sales?

We have always had a strong connection with Germany, so much so that we opened a branch in Munich in the 1980s. Today, this market represents over 50% of our turnover, but our distribution covers the whole of Europe. We have also recently begun to expand our presence in the United States through Amazon USA.

What is required today in terms of vision and investments to be competitive on international markets? (Technological innovation, research and development, digitalization of processes, reduction of CO2 emissions)

Let’s say that in general it is essential to be innovative, both in terms of industrial technological evolution, process optimization and reduction of their impact, and clearly in terms of the product. Consumer demands have changed and are changing over time and it is important to know how to grasp them and be able to satisfy them.

Where are your brands’ products developed, in terms of design, materials, etc.?

Our R&D department is internal to the company, here in Romano d’Ezzelino.

Having the DNA of the producers, we develop the design ourselves, collaborating closely with our suppliers of materials and technologies. The design always remains internal, but we use a pool of external stylists to enrich the creative process with new stimuli and ideas in line with the latest trends.

Referring to CMP, how often are the collections renewed?

I would say every season, certainly as regards the colour range, which is really wide), but more generally I would say that 70% of the collections are renewed every year.

Still in the CMP field, is there a genre that works better than the others?

No, we are very balanced, with about 30% for men, women and children. As for the latter, we are a point of reference, several brands no longer cover this segment of consumers as the margins are rather small.

Who are CMP’s competitor brands?

Taken individually I would say Icepeak, and Regatta Dare2b but our real competitors are the chain brands: Sport 2000, Cisalfa etc. chains that are then our points of sale. For this reason we have strengthened the network of our single-brand stores.

In a world where it seems that every new business initiative is generally aimed at a high-spending clientele, your brands seem to favor a good balance between quality and price and therefore a medium-level consumer target. This is one of the elements that most distinguishes you from your competitors.

In the high-spending segment there are many brands that battle it out on the fronts of innovation and technicality but it is also true that the real gap in these terms, compared to mid-range brands like CMP, has really narrowed over time. Just think of the fact that the suppliers of materials, technologies and labor are fairly shared among everyone.

Why then as CMP we are able to have competitive prices? Because we guarantee the supplier quantities that allow us to obtain low costs in the face of a high product quality.

As an industry media, we feel that high-end brands are struggling at the moment.

Of course, they are the ones who are suffering the most at the moment. The consumer has had less economic availability in the last 2, 3 years and has realized that it is not always necessary to invest large sums to buy a good quality item. And sometimes he has also become aware that he is not able to appreciate the performance of top-end products. The average consumer, in fact, is not an athlete nor does he practice sports at such high levels as to require extreme technical characteristics.

CMP is not just products for sports and outdoor: when was the Leisure line introduced, who is it aimed at and how is it performing?

Yes, we had been thinking about introducing a women’s leisure line (physical activity and homewear) for a long time and since it is part of our heritage we launched it with conviction. It will be available in stores starting in August, when we will start presenting the next autumn/winter collection. At the moment we have had excellent feedback from retailers and we are confident that end consumers will also like it.

In 2023 you launched the Jeanne Baret brand. In an Italian market where fashion, for everyday clothing, influences consumers so much, how was it received?

Jeanne Baret is a product with a strong identity and a clear target, which certainly needs to find its way from a distribution point of view. It is not a purely fashion or exclusively sports product, but a perfect balance between contemporary style and technical fabrics. It is designed for a dynamic and modern woman, who travels and looks for clothes that combine aesthetics and functionality. It works particularly well in the corners inside CMP stores, in single-brand stores and in medium-high range boutiques, especially in foreign markets.

In 2024, another novelty: Collective [of] Moving People is born, a brand aimed at GenZ and the ideals of fluidity, curiosity and independence that characterize it. What feedback have you received from the presentation in the Arsenale Venezia at the end of 2024?

We thought about the request for a brand dedicated to young people, lovers of skiing, snowboarding and steeped in contemporary urban culture, and that’s how Collective (of) Moving People was born. We worked with a new stylistic group, starting from a blank canvas. The feedback was good after the presentation in Venice, obviously now we will use our supplier and distribution system to make this brand known with new potential but still without a history.

What is the production process of a F.lli Campagnolo product? Let’s take a tour of the company

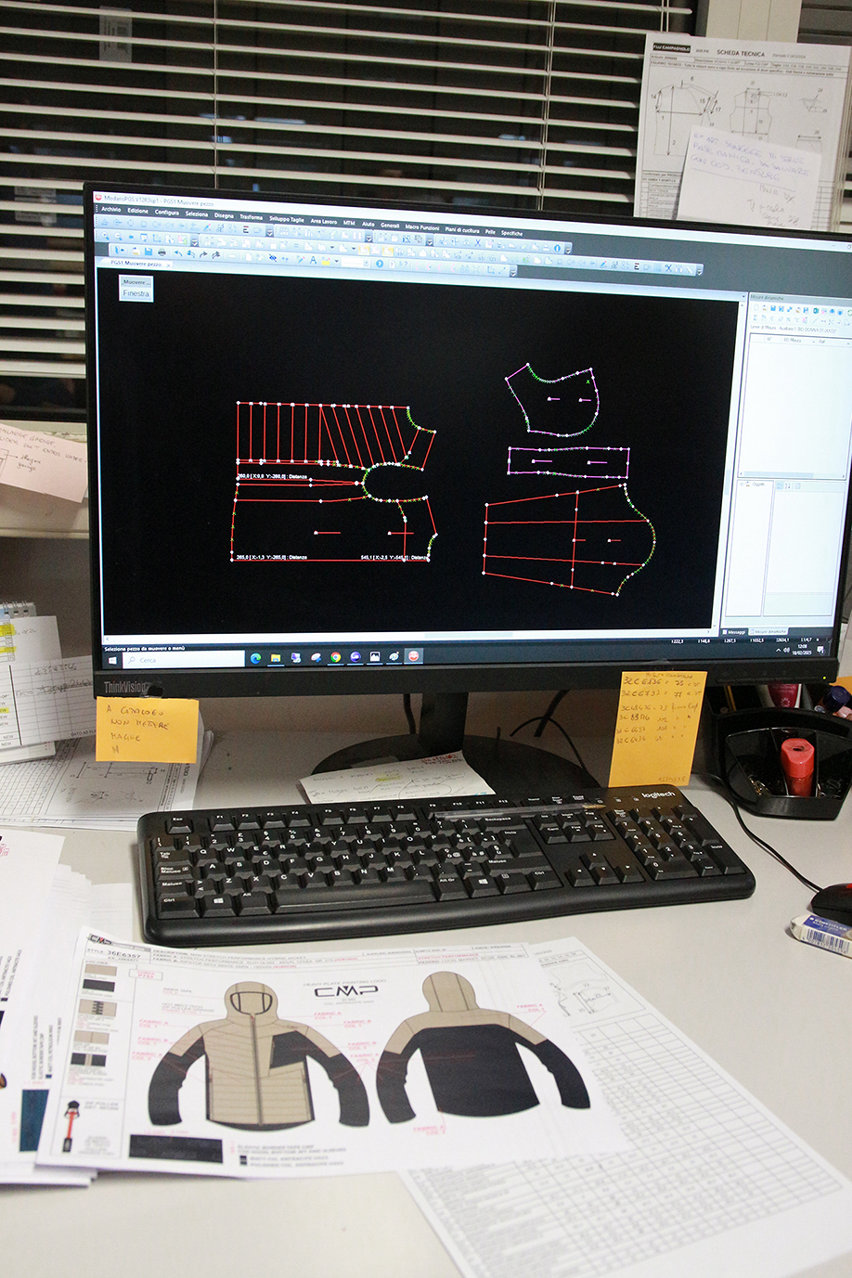

Interview with Guido Galvagni – Head of Models/CAD Office

When we pick up a piece of clothing in a store, we rarely ask ourselves how many steps were necessary to get it to our hands. Who designed it, who and where made the fabric, dyed it, cut it, sewed it, packaged it? How much did each of these phases affect the final price? Every product we use and wear is now the result of an industrial process, but that doesn’t mean that pressing a button is enough to make the product appear as if by magic, behind it there are always people, experience, progress and teamwork. The birth of a product is the result of a need, translated by the ingenuity of a designer, supported by a succession of professional figures and production processes that lead, through a long journey, to the final result.

Guido Galvagni – Head of the Models/CAD office, thirty years in the company, tells us about the evolution, the places and the process necessary to give birth to a garment of one of the F.lli Campagnolo brands.

F.lli Campagnolo has never been a company that markets products but rather a manufacturing company, with know-how that starts with the yarn, reaches the creation of the fabric, and so on to the finished product. When it was founded, the company, in its headquarters in Romano d’Ezzelino, took care of every step of the production process: from the creation of the fabric based on the yarn to finishing, from cutting to packaging, up to ironing. Over time, to meet growing demand, it became necessary to relocate some phases of production, relying on dozens and dozens of laboratories in the area, with an induced effect that employed thousands of people.

Subsequently, the increase in local manufacturing costs led to the need to relocate abroad. It was then that Mr. Giorgio Campagnolo opened a first production company owned in Romania, subsequently a second, with approximately 350 employees each, and finally a third based in Tunisia. The expansion of production volumes led over time to having to purchase ready-made fabrics, but the experience gained over the years has allowed us to carefully select suppliers, always maintaining high quality standards thanks to constant research and control work.

What remains today in the historic headquarters of Romano d’Ezzelino?

The creative heart of the company has remained here. The design, modeling and style development of the CMP, Jeanne Baret, Collective (of) Moving People, Melby and Maryplaid products are born in the headquarters.

We then have a prototyping department that allows us to contain times and logistics in the design phase. Keep in mind that the creation of a sample is a process that lasts four or five months, we multiply this by two collections a year and for all the brands of the group, we arrive at about 3,000 products per season (for each reference). Then there is a small cutting department and a customization department for small purchasing groups and a department called Fashion Studio, where we take photos of the products being worn. Finally, here are the marketing, communication, sales, etc. offices, as well as a large showroom. It is incredible how from that market stall in Bassano del Grappa, F.lli Campagnolo has become a player of international importance, evolving and adapting to the logic of a constantly evolving world. Yet in all this growth, one thing has not been lost, the identity of the founders and the brand, something that as Italians we can truly be proud of.